Insights Blog

Utilities Accounting: Capturing True Utility Costs in Process Industries

Introduction

Energy is often the single largest operating expense after raw materials for process manufacturers. These utilities - from electricity and fuel gas to steam, water, and compressed air - underpin every operation in a plant. Managing them well is crucial not only for cost control but also for optimizing production and meeting sustainability goals. Yet despite the high stakes, many facilities still rely on ad - hoc, non - systematic methods, often just spreadsheets, to track and allocate utility costs. For a process plant, a simple spreadsheet error in utility accounting might misallocate hundreds of thousands of dollars, undermining profitability and creating confusion.

Sigmafine offers a model - based mass and energy balance solution that turns raw utility data into reliable, auditable information for decision - makers. In this post, we explore how Sigmafine transforms utility accounting, ensuring accurate production data reconciliation, fair cost allocation, and seamless integration of utility data into finance and operations.

Challenges in Traditional Utilities Accounting

Non - systematic utility accounting practices pose several challenges for process industries:

- Data Silos and Inconsistency: Different units often maintain separate Excel sheets for gas, steam, water, air, and power consumption. Without a unified system, it’s difficult to reconcile these figures. Each spreadsheet might use its own assumptions or conversion factors, preventing a single version of the truth across the plant. Typos, broken formulas, or more simply discrepancies among different measurement cause frequent disputes between departments (operations vs. accounting, or site vs. headquarters) over how much utility was actually used and who pays for it.

- Lack of Transparency: It’s often unclear how utility costs are allocated to various processes or departments. When a bill arrives or a month - end report is produced, stakeholders may question the breakdown. Without clear, traceable logic, internal stakeholders and even external partners (e.g. a co - located facility buying steam) have little trust in the numbers.

- Infrequent Reconciliation: Many facilities only reconcile utilities on a monthly basis, if at all. This delayed insight means losses and inefficiencies (like a steam leak or an instrument error) might go unnoticed for weeks. In the meantime, money is literally evaporating.

- Audit and Compliance Risks: Utility costs feed into financial statements and environmental reports. When data is scattered in emails and spreadsheets, audits become a nightmare. It’s hard to prove where a number came from or to demonstrate compliance with internal policies and regulatory standards when there’s no clear audit trail.

In short, relying on spreadsheets and manual work for utilities accounting is error - prone, inefficient, and risky. A new approach is needed - one that uses rigorous data validation and reconciliation to ensure every megawatt - hour, cubic meter, and ton of steam is accurately accounted for.

A Systematic Solution: Model - Based Utility Data Reconciliation

Sigmafine is a model-driven software solution designed by Pimsoft to address these challenges by enforcing a continuous mass and energy balance across all utility networks. In essence, Sigmafine serves as a data reconciliation platform for production and energy data. It uses first - principles engineering models (conservation of mass and energy) and statistical methods to validate and correct measured data, yielding an accurate, single set of results. As a result, companies can extract high - quality, reliable information from raw sensor readings and disparate sources.

| Utility | Typical Balance type |

| Fuel Oil / Fuel gas

Natural gas Steam at different conditions Water Air / Nitrogen Power

|

Mass and/or Energy

Mass or (Std/Normal) Volume Mass and/or Energy Volume Std/Normal Volume Energy (e.g. KWh)

|

How does Sigmafine work for utilities accounting?

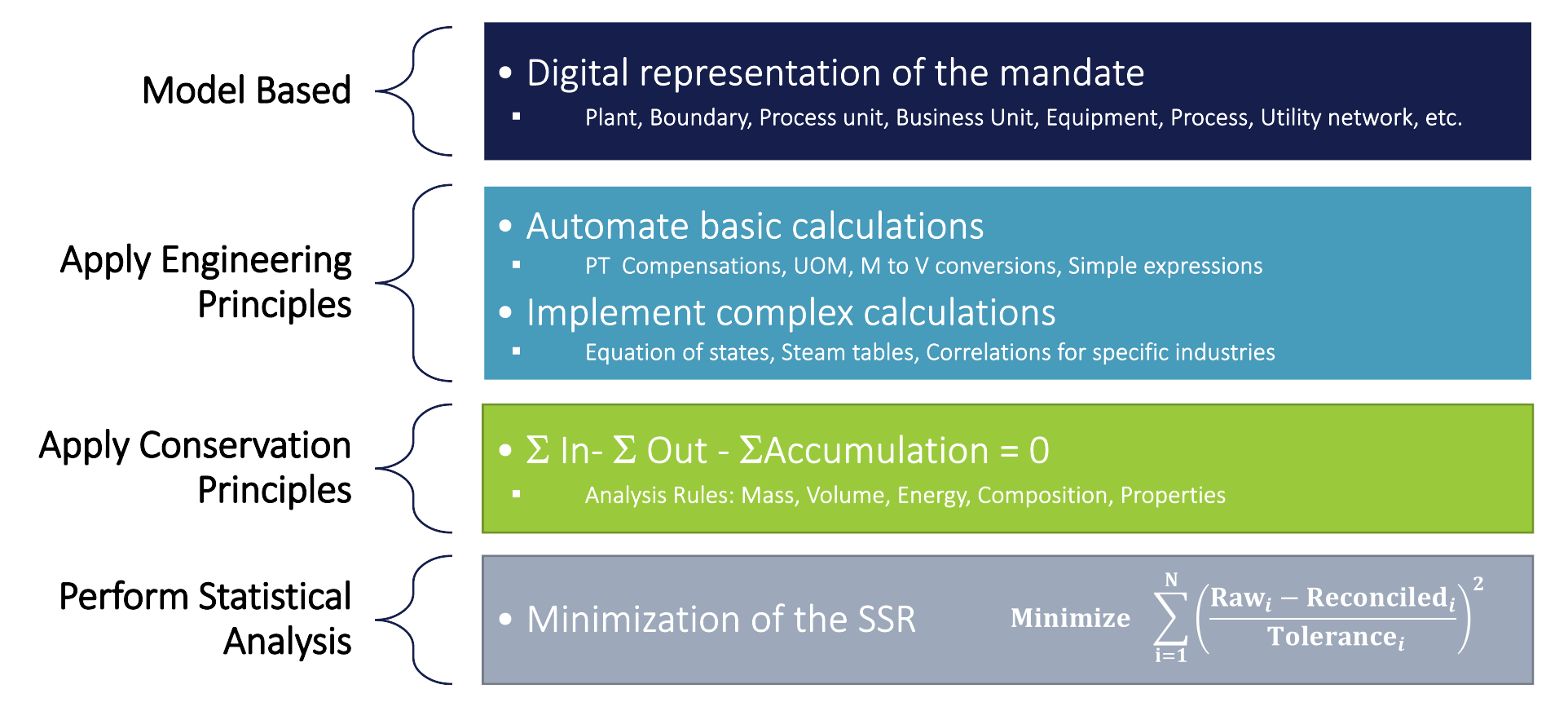

Sigmafine works by transforming raw utility data into accurate, trusted, and auditable information through a model - driven, engineering - based approach. It begins with a digital representation of the plant’s physical and logical structure (e.g. the utility network) ensuring all measurements are contextualized within a consistent operational model. Sigmafine then applies engineering principles to automate routine calculations and execute more complex ones such as compensations, conversions, steam table correlations, and industry - specific formulas. Using conservation laws, it balances all inflows, outflows, and accumulations of mass, volume, energy, and composition to ensure data integrity across the entire system. Finally, Sigmafine performs statistical reconciliation to minimize measurement errors and align raw data with expected operational behavior.

Sigmafine's data reconciliation process

The result is a reliable, reconciled dataset that empowers utilities accounting teams with precise consumption figures, loss detection, and actionable insights for process and energy optimization.

Sigmafine’s model - based approach turns chaotic utility data into a trusted, operationally valuable asset. Next, let’s look at specific value propositions and benefits this brings to an organization.

Key Benefits of Utilities Accounting with Sigmafine

Sigmafine delivers a comprehensive and intelligent solution to one of the most operationally critical and financially sensitive challenges in the process industries: accurate and auditable utilities accounting. Designed to support industrial utility complexity, Sigmafine delivers measurable value by enhancing data integrity, cost transparency, and cross - functional trust.

Supports All Utility Networks

Sigmafine models and reconciles all major utility networks - fuel gas, electricity, steam (at multiple pressure levels), compressed air, water, nitrogen, and more - in a single digital environment. This holistic view ensures that utilities are not tracked in isolation but are balanced and validated collectively, making the interdependencies between networks visible and manageable for operations and finance alike.

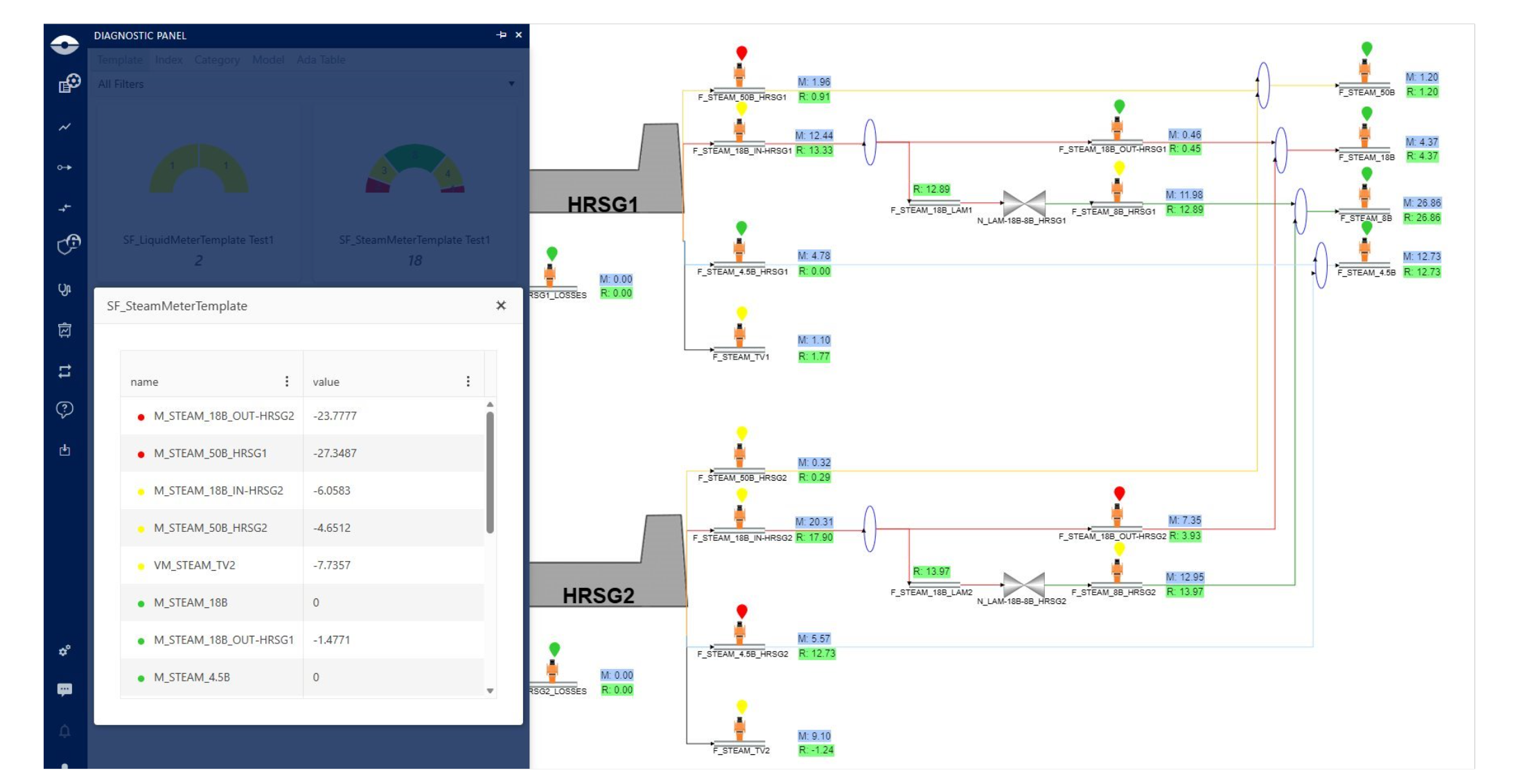

Example of Sigmafine's Steam Balance Network

Identifies Bad Measurements on Both Production and Consumption Sides

Using statistical data reconciliation and engineering rules, Sigmafine identifies and flags suspect meter readings -whether at the generation point (e.g., boiler output) or the consumption end (e.g., process unit intake). This allows engineers to detect faulty instruments or drift - prone sensors early, reducing uncertainty and preventing silent accumulation of cost or loss over time.

Delivers an Auditable System with Explicit Rules

Sigmafine operates on fully transparent, user - defined rules grounded in engineering and business logic. All balance constraints, allocation methodologies, and reconciliation parameters are explicitly configured and visible, allowing organizations to demonstrate exactly how utility costs and usage figures are derived - especially critical during internal audits or external inspections.

Tracks All Manual Changes

Any manual intervention in the data - be it a correction, override, or adjustment - is logged and traceable within Sigmafine. This level of control not only enforces accountability but also provides a complete history of how and why certain data points were adjusted, supporting change management, audits, and continuous improvement efforts.

Serves as an Objective Data Basis for Discussion Between Parties

In multi - plant sites, joint ventures, or shared utility scenarios, disputes over usage, allocation, or billing are common. Sigmafine’s reconciled and auditable dataset serves as a neutral, physics - based foundation that enables objective dialogue among internal departments or external partners - reducing friction and resolving conflicts with evidence - based confidence.

Provides Accurate Data to Financial Systems

Validated and balanced utility data can be automatically integrated into ERP systems like SAP or Oracle for booking, invoicing, and cost allocation. Everyone - from production accountants and plant managers to energy engineers and CFOs - works from the same trusted figures, ensuring consistency across operations, finance, and compliance reporting.

Compliance

Compliance is another area improved by Sigmafine’s rigor. Many companies have to comply with energy reporting standards, emissions trading schemes (where utility fuel usage correlates to CO₂ emissions), or governmental efficiency mandates. Sigmafine’s validated data can be used for regulatory reporting knowing that it meets accuracy requirements. For example, energy managers can more easily comply with frameworks like ISO 50001 (Energy Management).

Furthermore, internal compliance and governance benefit as well. Management can set policies using KPIs provided by Sigmafine (e.g. meter correction indicators) as a stimulus for continuous improvement. The software’s audit reports and alerts help enforce standard operating procedures for data management, which is a cornerstone of digital transformation and governance in modern plants.

Real - World Impact and ROI of Rigorous Utilities Accounting

Energy and utilities are too important and costly to manage with error - prone tools. By adopting a solution like Sigmafine for utilities accounting, process industry companies turn their raw utility data into a trusted asset. The benefits ripple across the organization: leading to better operations to improve consumptions and related emissions; accounting and finance gain confidence in the numbers (and spend less time reconciling books), and management can make better decisions with accurate, timely information.

Sigmafine’s mass and energy balance approach provides the accuracy, cost transparency, and audit - readiness that traditional methods lack. Whether you run a refinery, a chemical plant, a mining operation, or a power generation facility, improving your utilities accounting brings immediate ROI.

Customers using Sigmafine have reported improvements in the aggregated fuel and losses of up to 2% in 2 years, and reduction of the uncertainty of key parameters such as power plant steam turbine mass flow inlet by more than 20%.

Such outcomes represent recovered costs and efficiency gains that would have been impossible to attain with the old spreadsheet - driven approach. In an era of tight margins and sustainability goals, every kilowatt and BTU counts.

Ready to see how Sigmafine can transform your utility accounting and energy management? Contact your CSM representative at Pimsoft or Request a demo and discover the impact of “one version of the truth” for your organization’s utilities data.

Trusting Data for Action

In process and manufacturing, information systems should be implemented with a system of checks and balances to maximize the quality of data and the economic potential of data. Creating an environment where data can be trusted is not an afterthought. Data quality, similar to product quality, needs to be built into our business and data management activities so that we can trust data for action at all times.

Transforming Data into Digital Assets

Being digital refers to data and information stored digitally. Being an asset refers to having control of the data and information to produce positive economic value. Being a digital asset consequently refers to data & information we own and control and from which we can generate sustainable and tangible benefits. This has been the job of Sigmafine and its users for almost three (3) decades now.