Insights Blog

Insights into data management in the processs industries

Utilities Accounting

Dec 8, 2025

Utilities accounting in process industries is critical for cost control, energy optimization, and regulatory compliance. This blog explores how Sigmafine transforms raw utility data into accurate, reconciled, and auditable insights. By replacing spreadsheets with a model – based mass and energy balance system, Sigmafine enables fair cost allocation, detects losses, and supports ISO 50001 and sustainability goals – empowering engineers, accountants, and executives with trusted data.

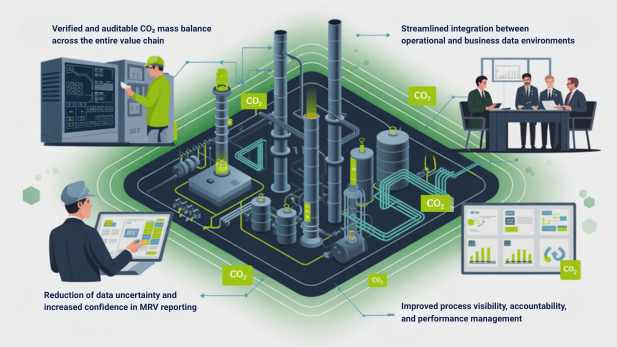

Building Trust in Carbon Accounting: How Sigmafine is Powering the Future of CCUS Data Integrity

Nov 17, 2025

Build carbon trust with Sigmafine—ensuring transparent CO₂ tracking and MRV compliance across every step of carbon capture, transport, and storage.

Carbon Capture, Utilization, and Storage (CCUS), data reconciliation, MRV (Measurement, Reporting & Verification), energy transition, and digital transformation in oil, gas, and chemicals.

Introduction to Sigmafine Express

Oct 29, 2025

Sigmafine Express is a cloud-based industrial software solution for data reconciliation and data conditioning in Oil & Gas, Chemicals, Petrochemicals, Metals & Mining and other industries with complex production processes. Learn how this data validation, recociliation and conditioning tool on AVEVA CONNECT ensures trusted, reconciled process data with minimal on-premise infrastructure.

Workflow Planning in Oil and Gas: Why Data Quality Is the New Competitive Advantage

Jun 27, 2025

Workflow Planning in Oil and Gas: Why Data Quality Is the New Competitive Advantage Q: Why is high-quality process data critical for refinery workflow planning? A: In oil refining, missing or inaccurate data comes at a high cost. Without trustworthy process data, planning and decision-making suffer – leading to unaccounted losses, regulatory compliance risks, and […]

How Chemical Companies Are Turning Messy Data into Actionable Insights

Jun 2, 2025

Chemical producers struggle with messy, siloed data. Learn how “data conditioning” transforms raw data into reliable insights for better decision-making.

Data Conditioning

Apr 11, 2025

Discover how data conditioning transforms raw process data into valuable digital assets for advanced analytics and digital transformation. Learn about cleansing, validation, reconciliation, and the role of infonomics in creating high-quality datasets that drive operational excellence in process industries.

Transforming Data into Digital Assets

Mar 13, 2021

Being digital refers to data and information stored digitally. Being an asset refers to having control of the data and information to produce positive economic value. Being a digital asset consequently refers to data & information we own and control and from which we can generate sustainable and tangible benefits. This has been the job of Sigmafine and its users for almost three (3) decades now.

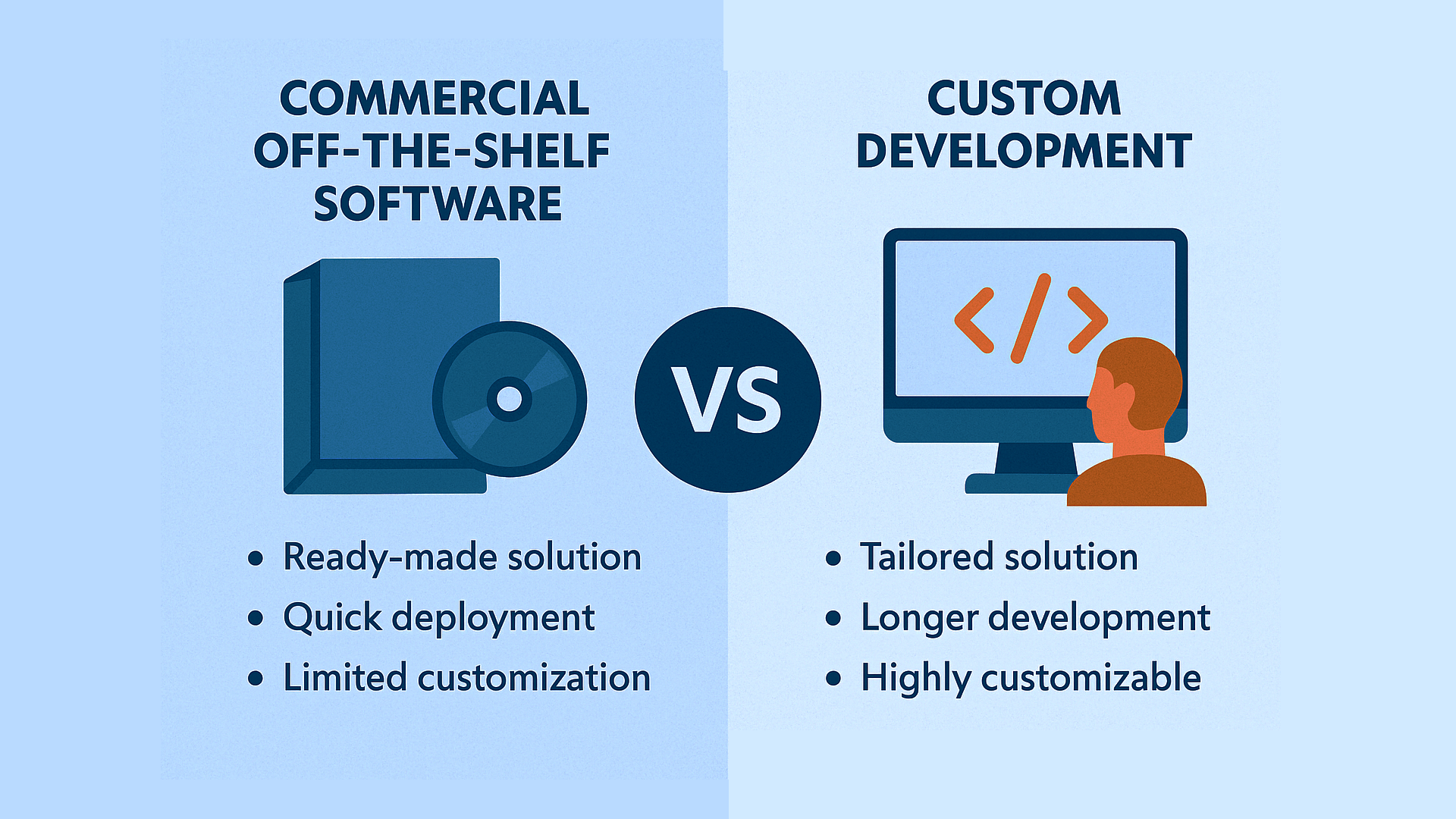

COTS vs. Custom Development Pros & Cons

May 27, 2020

As a solution provider for the OSIsoft PI System, we are often asked about commercial off the shelf software (COTS) vs. custom development. It is a good question. Here are our thoughts:

Tolerance for bad data

Nov 23, 2019

Whether it is called “Industry 4.0”, “Edge Computing”, “Big Data” or “IOT”, the tolerance of People, Applications and Business Processes to poor data quality in industrial plants is diminishing rapidly. The Modern process industries thrive on readily usable information and credible data to deliver sustainable tangible business results.

What is the Industrial Plant Dataset

Sep 3, 2018

The “Industrial Plant Dataset” is a complex amalgam of synchronous and asynchronous data types and data sources which must be collected, checked, structured and organized to service the business and operational scenarios of users, applications and business process.

Data Quality, a two-sided Benefit Model

Jul 7, 2017

The business case for improving Data Quality is blessed by a two-sided benefit model: downside avoidance & upside realization. Data Quality professionals have a rule which they call the “Rule of 10”: “It costs 10 times as much to complete a unit of work when the input data are defective as it does when they are perfect”.

Defining Data Quality in the Process Industries

Oct 15, 2016

Data Quality is an abstract concept until we are confronted with bad data or information which is not usable, not credible, not presented correctly, not accurate, etc.. Then Data Quality becomes a very concrete experience. While, there are many definitions for Data Quality, all of them converge to the same focal point. “fitness for use” by people, applications and business processes.

Trusting Data for Action

Jul 15, 2015

In process and manufacturing, information systems should be implemented with a system of checks and balances to maximize the quality of data and the economic potential of data. Creating an environment where data can be trusted is not an afterthought. Data quality, similar to product quality, needs to be built into our business and data management activities so that we can trust data for action at all times.